Recycleye

« Developed specifically to detect waste items as accurately as a human eye »

Why you need to contact Recycleye?

- Recycleye Robotics is always there, always picking, 24/7

- Help reduce your costs and drive profit by automating manual picking operations

- Recycleye’s technology is installed in locations across Europe and the United States

Recycleye Robotics uses AI-powered sorting to help reduce your costs and drive profit by automating manual picking operations. Our technology is retrofittable without major plant modification and enables sorting to accuracy not previously possible, whilst also lowering the cost of your QC.

Our offer

Traditionally, the cost of sorting precious resources has been greater than the value gained from selling them. That changes now, thanks to innovative data-driven waste sorting technology from Recycleye, up to the task of sorting waste streams – faster, smarter and more reliably.

Founded in 2019, and now grown to a team of 50 technical and commercial experts based in the UK and France, Recycleye’s technology is installed in locations across Europe and the United States, working for clients to add value to their sorting operations through increased purity and outputs.

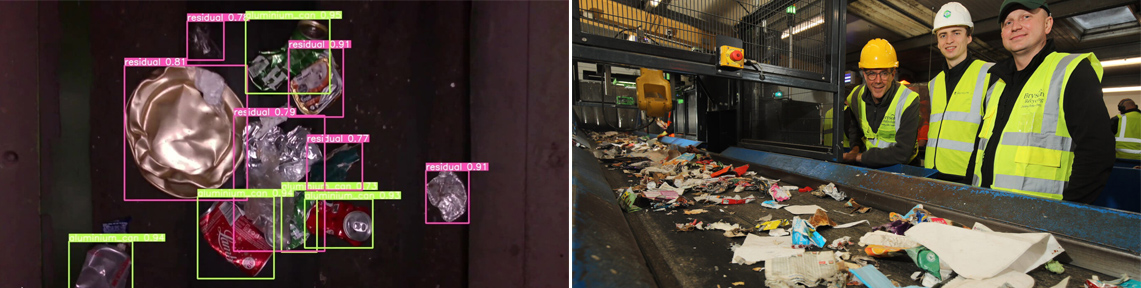

- Recycleye Robotics are AI-powered robots designed to pick dry mixed recyclables in Materials Recovery Facilities (MRFs).

- Developed in collaboration with leading robotics manufacturer FANUC, we offer ongoing end-to-end support, trusted ideas and expertise at every step, which means our clients benefit from solutions that are right for their MRF.

Advantages

Recycleye is bringing ground-breaking, robust technology to reduce the cost of DMR waste sorting and QC in MRFs. We partner with our clients to deliver tailored solutions that support profitability and meet specific needs such as improving output quality on plastic, non-ferrous and fibre waste lines.

Our industry-leading AI was developed specifically to detect waste items as accurately as a human eye and it generates strategic data to support decision making with every item it scans.

Recycleye Robotics is always there, always picking, 24/7. It uses a 6-axis robot arm, easier to retrofit over existing belts, with no major plant modifications required and has sensors to detect issues through remote-monitoring to ensure efficient operation. For peace of mind, our customers’ installations are supported end-to-end by our expert engineers, underpinned by the European maintenance network of global robotics leader FANUC.

Recycleye

Waste / Recycling, reuse, repurposing

« Developed specifically to detect waste items as accurately as a human eye »