Subor

« Subor provides accurate solutions for a wide variety of projects by manufacturing pipes in a range between 200 mm and 4000 mm in diameter »

Why you need to contact Subor?

- Non-corrosive materials

- Excellent impact resistance

- Subor provides accurate solutions for a wide variety of projects

Our company

Why subor ?

Presence in 5 continents

Reliable and long-life piping solutions enable civilizations in different territories to reach clean water and energy.

Experience

More than 10.000 km of subor pipes in various applications are serving the development of humankind, worldwide.

Field service

By aiming to extend the service life of the pipe system with the correct installation in a cost-effective way, subor is providing site supervision service all over the world ensuring the conformity with the technical specifications and standards.

Engineering and r&d

Subor’s in-house engineering department delivers the design works and calculations according to piping principles in each project, develops researches and innovates new products.

High production capacity

With an installed manufacturing capacity of over 1.000 km pipes per year, subor is one of the world’s leading grp pipe producers.

Efficient use of transportation

Wide experience in cost-efficient transportation solutions by means of truck, container, bulk-shipment, train and their combinations, together with the lightweight of grp pipes enable the end-user to reach attractive freight charges globally.

Wide range of products in pipe systems

Subor provides accurate solutions for a wide variety of projects by manufacturing pipes in a range between 200 mm and 4000 mm in diameter, up to 40 bar pressure and 1.000.000 n/m? Stiffness.

Non-corrosive materials

Corrosion, the major environmental risk imposed by pipeline projects is not a problem with grp pipes. When it comes to long term use, grp is your go-to option for both environmental and financial impact.

Environment friendly

By aiming to leave a better world to the future, subor accepts the principle of respecting the environment and nature in all of its processes within the awareness of environmental responsibility.

Quality assurance

Subor grp pipes are designed and tested in compliance with the world’s fundamental and acknowledged standards such as awwa, astm, iso, en, din, bs.

Project finance

Subor provides soft loan by international export credit agencies to projects in order to accelerate the investment return.

Sustainable investment

Having a very low carbon footprint due to their high level of material efficiency, subor grp products are the best choice for the environment, compared to conventional pipe technologies.

Our offer

Grp :

Subor’s approach to a more sustainable business to undertake today’s projects with respect to future generations’ needs. Sustainable development must consider the effects it has on the economy, society, and environment as a whole. Subor, as a pipe manufacturer calculates the influence of its outputs on these elements at every step of its decision-making process for a sustainable business.

The superior properties of grp in terms of excellent hydraulic characteristics resulting in higher energy productivity and less pumping energy, high efficient production and transportation methods together with its long life cycle enable subor to offer the utmost quality with better sustainability to the future. As a result of having very low environmental impact compared to conventional pipe technologies due to its high level of material efficiency, subor grp products have low.

You shape it we make it

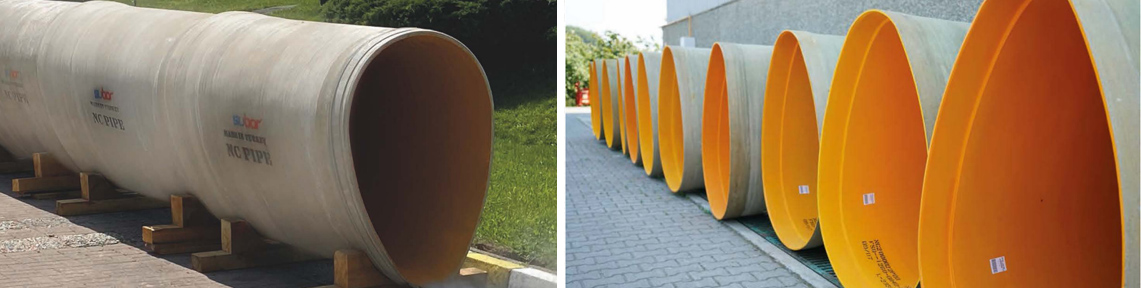

Subor non-circular (nc) grp pipes are primarily designed and developed for use in buried installations and commonly to reline existing non-circular pipelines.

The application areas of subor nc pipes are :

- Sanitary sewer and old city sewer relining.

- Storm water conveyance.

- Chemically aggressive sewerwater.

- The subor nc pipes offer the following advantages to the end-users :

- Custom pipe lengths and profiles.

- Long and effective service life.

- Excellent impact resistance.

- Increased chemical and abrasion resistance.

- No need for additional lining or corrosion protection.

- Superior hydraulic characteristics.

- Lightweight, easy joining and fast installation.

- Environmental friendly.

Production process

Subor nc grp pipes are manufactured in a filament winding technology controlled by a plc system that involves the winding of the glass fibers around a rotating structure called mold. The glass fibers wound around the internal and external resistance layers to ensure the nc pipe’s resistance

And rigidity, and the chopped glass fibers used on all layers to ensure axial resistance. The raw materials are bound by the thermoset polymerization reaction of the polyester. The filling material (silica sand) is used on the central layer to enhance the pipe rigidity in a cost effective way.

Fittings freedom to-choose

Subor nc grp pipes are also used to fabricate fittings such as elbows, tees, wyes and manholes, which can be designed on specific demand. Subor offers wide solution opportunities with over 200.000 different types of fitting design.

Advantages

SUBOR’s approach to the quality concept is not limited to the production process and its product. The management mindset of SUBOR in all activities is an insight that considers the satisfaction of all stakeholders, especially the customers and adopts occupational health and safety as the fundamental policy.

Having established its management system upon such foundations, SUBOR has obtained certificates for ISO 9001 Quality Management, ISO 14001 Environmental Management, OHSAS 18001 Occupational Health and Safety Management and ISO 27001 Information Security Management System.

Subor

Contaminated Sites and Soils / Contaminated sites and soils

« Subor provides accurate solutions for a wide variety of projects by manufacturing pipes in a range between 200 mm and 4000 mm in diameter »